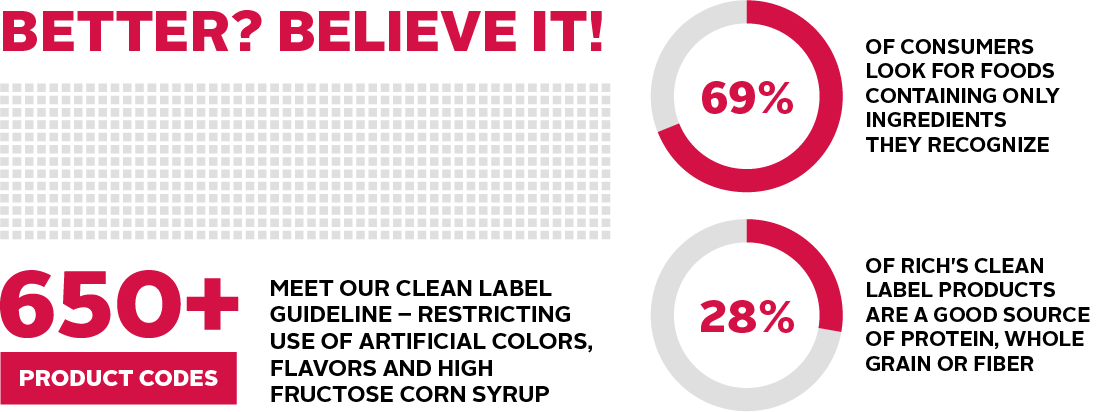

It’s no secret – consumers are searching for healthier food options across every category – from prepared foods and C-stores to restaurants, foodservice and more.

That means simple, recognizable ingredients. Clean label food free of additives and artificials. Gluten-free, plant-based and responsibly-sourced options. All that deliver a fresher, better-for-you food experience, without compromising on taste.